Publish date: 2026-01-09

Ceramic structural components are one of the core parts of a piece of equipment; choosing the wrong one can lead to soaring costs and equipment failure. Don't panic! Master these 4 core steps, and even as a procurement novice, you can quickly match the right ceramic structural parts.

High temperature? Corrosion? Wear? The working environment determines the type of structural ceramic material.

Clarify the performance focus of the ceramic components for your equipment to avoid "using a sledgehammer to crack a nut" or "under-powering a heavy load."

| Requirement | Recommended Material | Typical Applications |

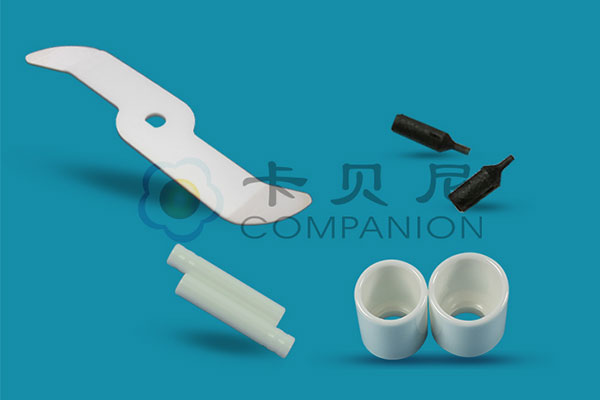

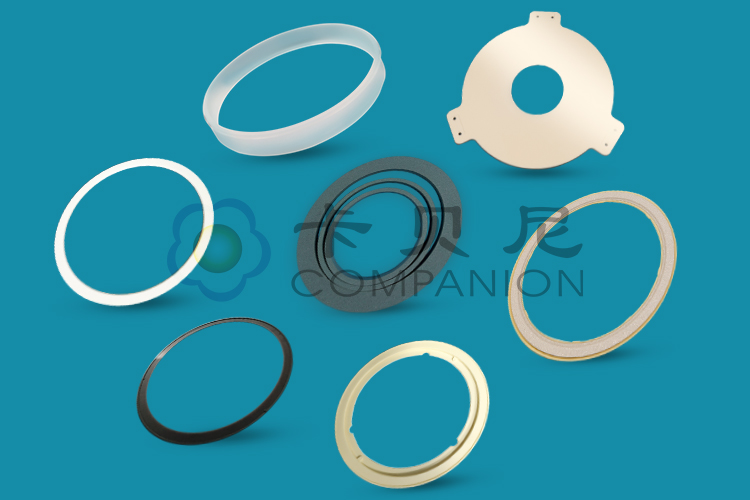

| High Hardness/Wear Resistance | Alumina, SiC, Zirconia, Si3N4 | Bearings, Seals, Grinding Balls, Blades |

| High Strength/Compression | Alumina, Silicon Nitride | Industrial Supports, Reactor Linings |

| Insulation/Heat Dissipation | Alumina, Aluminum Nitride | Electronic Substrates, Insulating Sleeves, Heat Sinks |

| Low Friction | Zirconia, Silicon Nitride | High-speed Bearings, Sliding Parts, Gas Seals |

Price differences for ceramic structural parts are significant. Choose a cost-effective solution based on your budget.

Economic Grade: Alumina Ceramics

Alumina ceramics have abundant raw materials and mature processes, resulting in low unit prices. They are suitable for conventional electronic insulating parts and wear-resistant liners.

Mid-Range Grade: Aluminum Nitride / Zirconia Ceramics

Aluminum Nitride offers excellent thermal conductivity for cooling; Zirconia is hard and tough, suitable for high-end bearings and medical components.

High-End Grade: Silicon Nitride / Silicon Carbide Ceramics

These withstand harsh conditions such as extreme heat and corrosion. However, complex preparation and high purity requirements keep costs high.

Specialty Grade: Yttria Ceramics

Yttria ceramics are used in specialized fields like optics and high-temperature detection. Despite the high cost, their unique performance is irreplaceable in specific high-end scenarios.

|

|

|

|

|

|

Dimensional accuracy directly affects component assembly and equipment stability. Companion provides full-chain precision solutions: from initial DFM analysis to CNC precision machining. We can meet strict micron-level requirements while optimizing tolerance design for the best cost-effectiveness.

We have focused on advanced material solutions for over 20 years, serving 100,000+ projects across electronics, machinery, and medical devices. Whether your requirement is for wear resistance, insulation, or high-temperature resistance, we can provide a customized solution.

Companion has built a strict quality control system from Raw Materials to Finished Products. We also support special requirements such as the metallization of ceramic structural parts.

We offer three modes: processing from drawings, development from samples, and collaborative R&D. We achieve fast delivery for standard parts and efficient execution for complex parts.

Inquire Now to Get an Exclusive Customized Solution and Quote!