Publish date: 2026-01-19

Are you facing these persistent challenges after years in the precision manufacturing industry?

Metal components wear out rapidly, leading to skyrocketing maintenance costs; materials lose their performance integrity in high-temperature environments, hindering production efficiency; signal interference in electronic devices causes unstable product yields; and critical parts in medical devices demand extreme reliability and durability, yet finding the right material seems impossible...

Every material selection feels like a high-stakes gamble. Choosing the wrong one increases costs and reduces efficiency at best—and at worst, leads to catastrophic project failure and immeasurable losses. As companies search for a definitive solution, one material has quietly emerged as a versatile answer to these challenges: Alumina Ceramics.

How does it solve multiple problems with a single material? Let’s explore below.

Alumina Ceramics (Chemical Formula: $Al_2O_3$) are high-performance materials renowned in the industrial world. Existing in nature as minerals like corundum, Alumina is a true "performance powerhouse" with several key traits:

Common types based on Alumina content include 99%, 99.5%, and 99.7% Alumina Ceramics. Parameters such as density and thermal conductivity vary by formulation. For specific material data, please contact Companion customer service.

|

|

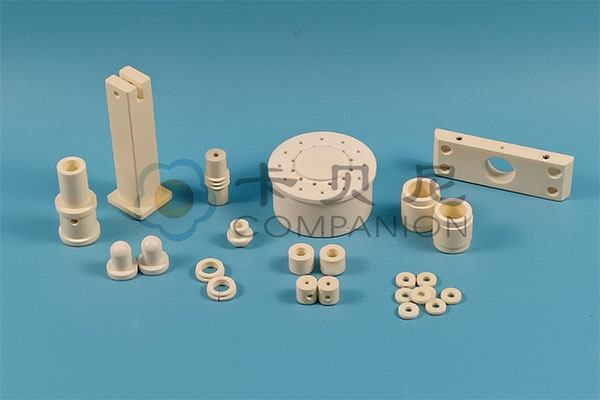

Precision in electronics requires strict insulation and stability. Alumina Ceramic Insulating Sleeves leverage excellent dielectric properties to isolate components and prevent short circuits. Alumina Ceramic Windows are widely used as inspection ports for electronic components due to their stable electrical and chemical properties. Additionally, Alumina Vacuum Chucks are essential for high-precision mounting and handling; they provide superior flatness and stable suction to securely grip micro-electronic components, avoiding the electrostatic damage and gas contamination common with traditional metal chucks.

|

|

Mechanical equipment must endure high friction, pressure, and complex operating conditions. Alumina Ceramic Guide Rails offer high dimensional accuracy and surface flatness, enhancing precision in high-end machining equipment. Alumina Ceramic Arms (Ceramic End Effectors) combine lightweight properties with high strength, providing better corrosion and wear resistance than metal arms in automated production lines.

|

|

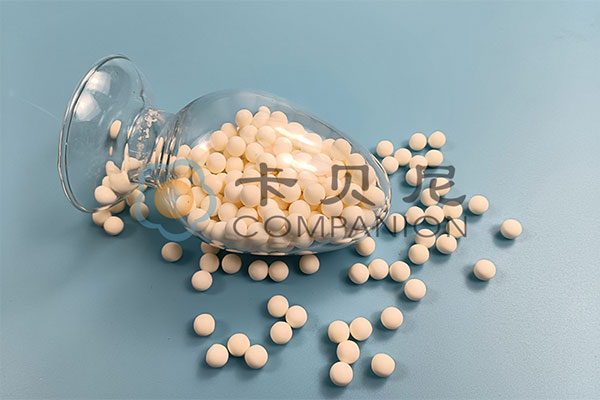

Chemical production often involves highly corrosive, high-temperature, and high-pressure environments. Alumina Ceramic Nozzles, with their superior corrosion and wear resistance, withstand the scouring effects of corrosive liquids and gases, ensuring process stability. Alumina ceramic plates/liners used as equipment linings or sealing elements protect substrates from aggressive media, extending equipment life. Furthermore, 99.7% High-Purity Alumina Ceramic Balls serve as specialized grinding media for crushing and dispersing electronic powders, pigments, and glazes. Their high density and wear resistance improve grinding efficiency while ensuring the purity of fine chemical products.

Alumina ceramic components are driving technological upgrades in NEVs. Ceramic Bearings, offering insulation, high-temperature resistance, and lightweight advantages, are gradually replacing metal bearings in critical applications such as motor spindles.

In 5G communication technology, Alumina ceramic substrates are a core material. Their high dielectric constant and excellent thermal conductivity optimize signal transmission and heat dissipation, enabling low-loss high-frequency broadband transmission and supporting the miniaturization and cost reduction of 5G equipment.

The performance advantages of Alumina ceramics span across electronics, machinery, chemicals, new energy, and communications. As a specialized Alumina ceramic processing manufacturer, Companion provides one-stop customization services from formula design to precision machining:

In the diverse landscape of precision manufacturing, Alumina ceramics provide a material choice that balances reliability with cost-effectiveness. Companion does not just provide ceramic material solutions; we specialize in deconstructing the details of your operating conditions—from material properties to structural design—to create highly adapted, customized solutions for our clients.