Publish date:2026/02/14

In the process of modern industry moving towards higher precision, precision ceramics—also known as advanced ceramics or technical ceramics—have become indispensable core materials. Unlike traditional ceramics, precision ceramics utilize high-purity synthetic powders and undergo rigorous process control to exhibit exceptional hardness, superior high-temperature resistance, and excellent electrical insulation properties.

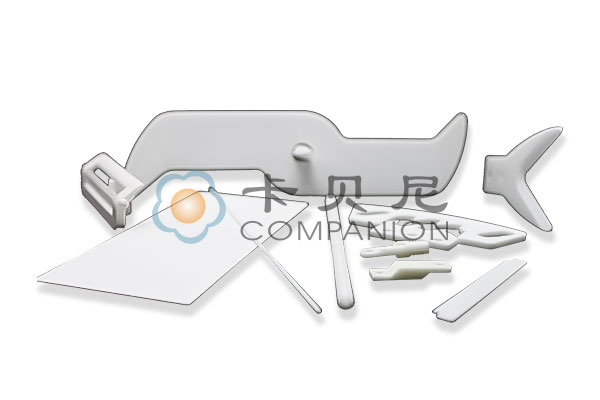

As a dedicated player in the field of precision ceramics, Companion is committed to providing high-performance ceramic components for cutting-edge industries such as Electronic Engineering, Automotive & Transportation, Machinery & Equipment, Medical Devices, Display & Lighting, and Energy.

|

The "precision" of precision ceramics stems from the mastery of the microscopic world:

(1) High Purity and Fine Grains: Powder raw materials with a purity typically no less than 99.7% are used. Low impurity content effectively reduces brittle phases at grain boundaries, enhancing the mechanical reliability of the material. Simultaneously, by optimizing sintering parameters, grain sizes are controlled at the micron or nanometer scale. Uniform grain distribution contributes to improved fracture toughness and compressive strength.

(2) Degree of Densification: Technologies such as Hot Isostatic Pressing (HIP) or controlled atmosphere sintering are utilized to effectively reduce residual porosity within the ceramic. A high-density microstructure not only improves mechanical performance but also ensures excellent vacuum tightness and dielectric strength for components in precision electronic environments.

(3) Functional Doping: By introducing specific trace elements into the matrix, thermal conductivity, coefficient of thermal expansion, or piezoelectric effects can be precisely adjusted to adapt to complex industrial environments.

(1) Powder Preparation: Wet ball milling or spray drying technologies are employed to ensure uniform particle size distribution and good fluidity of the powder.

|

|

Powder Preparation |

(2) Forming Processes

|

|

Forming Processes |

(3) High-Temperature Sintering: Sintering is conducted at high temperatures; some high-performance parts must be completed under a controlled atmosphere to prevent oxidation-reduction reactions.

|

|

High-Temperature Sintering |

(4) Precision Machining: Using diamond grinding, lapping, and polishing to achieve micron-level dimensional tolerances and surface finish.

|

|

Precision Machining |

| Material | Formula | Key Features | Typical Applications |

|---|---|---|---|

|

Al2O3 |

Excellent insulation, wear resistance, chemical stability |

Electronic substrates, insulating seals |

|

|

ZrO2 |

High toughness, low thermal conductivity, biocompatible |

Pump valves, medical restorative materials |

|

|

Si3N4 |

Thermal shock resistance, high strength, friction resistance |

High-speed bearings, heat treatment parts |

|

|

AlN |

Extreme thermal conductivity, matched CTE |

High-power heat sinks, electronic supports |

|

|

SiC |

High rigidity, thermal conductivity, corrosion resistance |

Heat exchangers, processing carriers |

Precision ceramics are the foundational support materials for modern electronics. Alumina and aluminum nitride are widely used in packaging substrates and insulating gaskets. In precision equipment, silicon carbide is often processed into ceramic vacuum chucks and robotic arms to ensure stability in high-temperature or vacuum environments.

|

In LCD/OLED production, precision ceramic parts like guide rails and positioning elements provide dimensional stability and reduce particle contamination. Ceramic heat dissipation substrates are also vital for high-power LEDs.

Companion provides nozzles and valve cores with extreme chemical inertness, enabling equipment to operate stably in strong acid and alkali environments.

|

(4) Medical Devices & Life Sciences

High-purity zirconia is commonly used for surgical tools and plungers due to its biocompatibility. Its non-magnetic nature makes it ideal for MRI environments.

|

(5) Automotive Industry & Intelligent Transportation

Ceramic materials are used in sensors, insulators, and NEV high-voltage relays, as well as LiDAR components, due to their superior electrical insulation.

(6) Mechanical Equipment & Precision Machining

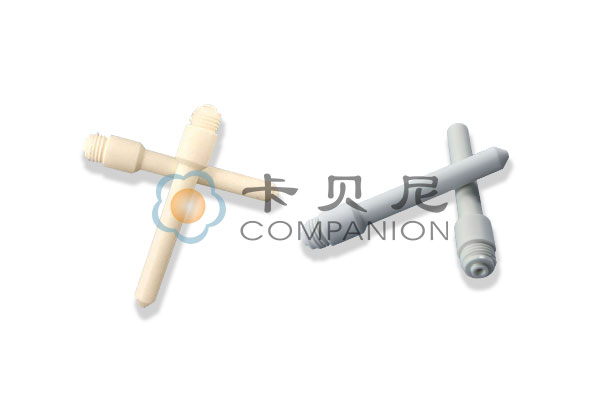

Ceramic nozzles, ball bearings, and plungers extend equipment life in automated lines through exceptional hardness and wear resistance.

(7) Optical Components & Precision Instruments

Precision ceramics' low CTE makes them the preferred choice for structural frameworks in optical testing instruments to avoid dimensional deviations.

How to choose precision ceramic materials based on operating conditions? Consider these factors:

(1) Thermal Performance: Handling High Temperatures and Thermal Shock

Silicon Nitride (Si₃N₄) is suitable for rapid thermal shock; Aluminum Nitride (AlN) is the superior choice for high thermal conductivity.

(2) Electrical Performance: Insulation vs. Heat Dissipation

Alumina (Al₂O₃) and Aluminum Nitride (AlN) are excellent insulators, while Silicon Carbide (SiC) is common for precision electronic processes needing heat dissipation.

(3) Mechanical Performance: Balancing Hardness and Fracture Toughness

Zirconia (ZrO₂) offers high fracture toughness for mechanical impact, whereas Silicon Carbide provides high rigidity and surface wear resistance.

(4) Chemical Performance: Corrosion Resistance in Acid/Alkali Environments

Silicon carbide and high-purity alumina offer excellent chemical stability, reducing part loss due to corrosive reactions.

(5) Biological Properties: Biocompatibility in Life Sciences

High-purity zirconia and alumina are used for medical ceramic pump components and implant-grade parts due to their non-toxic nature.

Precision ceramics have become indispensable core materials of modern precision industry. Companion focuses on the R&D and custom processing of advanced structural ceramics to provide technical support to global customers.

If you have requirements for material selection or custom processing, please feel free to Contact Companion. Our technical team will provide optimized customized solutions.