Publish date: 2024-11-08

Ceramic end effectors, also known as ceramic robot arms, ceramic handling arms, or ceramic fingers. They are used not only in the electronics industry, meeting the stringent standards of high cleanliness, stability, precision, efficiency, and reliability, and precisely executing critical tasks such as component handling, transportation, and positioning in micro- and nano-fabrication processes; but also showcase broad application prospects in medical, chemical, food processing, mechanical equipment, and other fields due to the advantages of high-performance ceramic materials.

The main materials of ceramic end effectors include alumina ceramics, silicon carbide ceramics, etc. These materials possess physical properties of high density, high hardness, high wear resistance, as well as high-temperature stability and chemical inertness. They can repeatedly enter and exit to transport products in high-temperature and normal-temperature working environments, maintaining good mechanical strength even under repeated temperature changes. In the modern industrial field, ceramic end effectors, with their unique technological charm and excellent performance, are gradually becoming a key support for many high-tech industries.

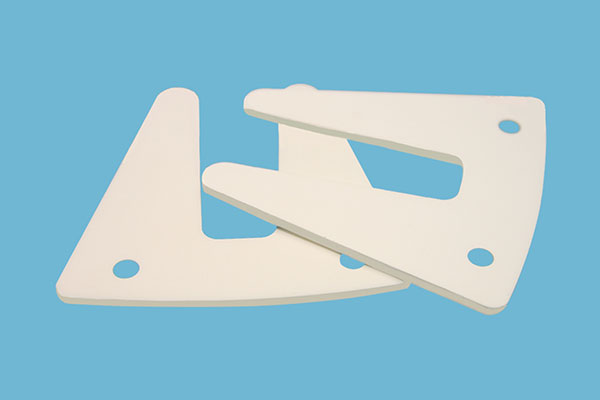

Companion's independently developed alumina ceramic end effectors are made of high-purity alumina granulations, with stable chemical properties. In contact with objects, they not only leave no contaminating fine particles, but also avoid the generation of charged charges and the release of metal ions, which can effectively prevent pollution to electronic component production. Alumina end effectors integrate multiple advantages such as good mechanical strength, wear resistance, heat resistance, insulation, and high hardness. In the field of electronic engineering, facing the complex electrical environment intertwined with high temperature and corrosive gases, it can still stably and efficiently complete the precise positioning and handling tasks of electronic components.

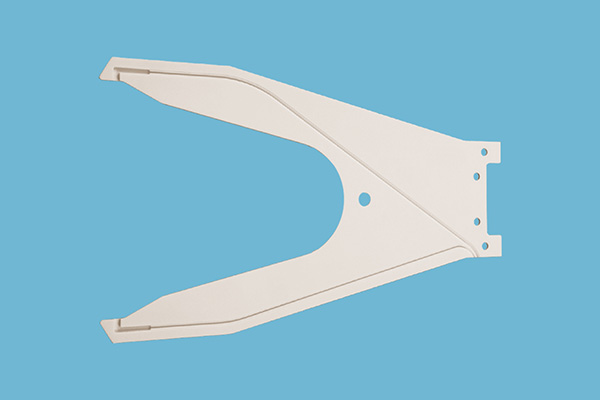

Silicon Carbide Ceramic End Effector is based on advanced silicon carbide ceramic materials, which not only inherit many advantages of alumina, such as high mechanical strength, wear resistance, heat resistance, and insulation, but also set a new benchmark in terms of hardness and thermal shock resistance. Compared with alumina, silicon carbide ceramic end effectors perform particularly well in high-temperature environments. Its thermal expansion coefficient is lower, which means that silicon carbide end effector can maintain smaller dimensional changes and maintain higher precision and stability under extreme temperature fluctuations.

In addition, the electrical conductivity and high thermal conductivity of silicon carbide ceramics enable it to conduct electricity and heat better, and take away the residual charges of the reaction products, avoiding interference with the other processes of the transported items, and further improving the efficiency of silicon carbide end effector in a variety of industrial application scenarios.

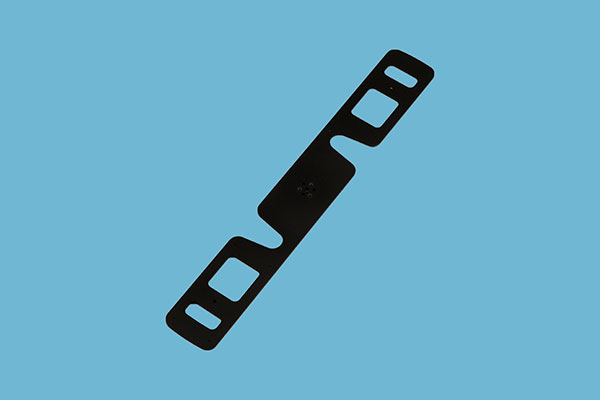

Teflon-coated ceramic end effectors refer to a layer of black Teflon anti-static coating on the high-performance alumina ceramic substrates. Teflon, as a pioneer of non-stick coatings, is known for its extremely low friction coefficient, which greatly reduces the resistance and wear during the handling of electronic components, ensuring high-precision and high-efficiency operation.

At the same time, the coating is almost unaffected by most drugs and chemicals, providing all-round protection for the mechanical arm, protecting it from chemical corrosion and extending its service life. The black Teflon anti-static coating can effectively inhibit the generation of static electricity. This is crucial for the production of precision electronic components, and it can prevent component damage caused by electrostatic discharge, ensuring the safety and stability of the production process.

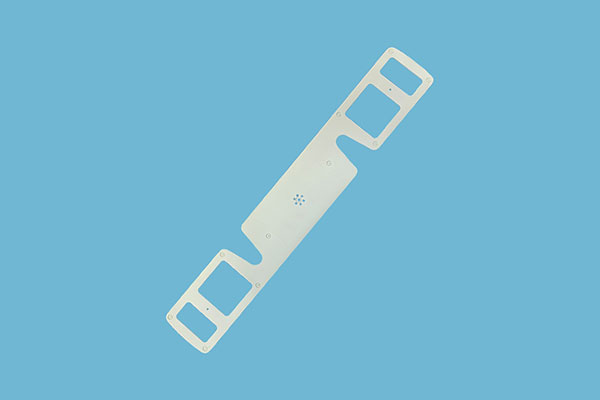

|

|

| Before Coating | After Coating |

Companion can provide non-standard size customization services to meet the personalized needs of different customers. Whether you are looking for specific advanced ceramic materials, special coatings, or need customized designs for different application scenarios, Companion can provide you with comprehensive solutions!